As part of an ongoing discussion with a fellow ham up in New York, I thought I’d share a little virtual tour of my soldering/desoldering and SMD rework center. This setup is the

The equipment is housed in a roll-around A/V cart which I picked up last year at a great price. It turned out to be perfect for the job.

result of equipment put together over the course of 36 years. There are still two more pieces of equipment I wish to add: a board prewarming unit, and a reflow oven. I will build the reflow oven by converting a toaster oven. I’m not sure how soon that will happen, but when I do I’ll share the details and results. Meanwhile, here is my current setup.

The main equipment consists of:

- Zeny Hot Air and Pencil SMD Rework Station (top shelf)

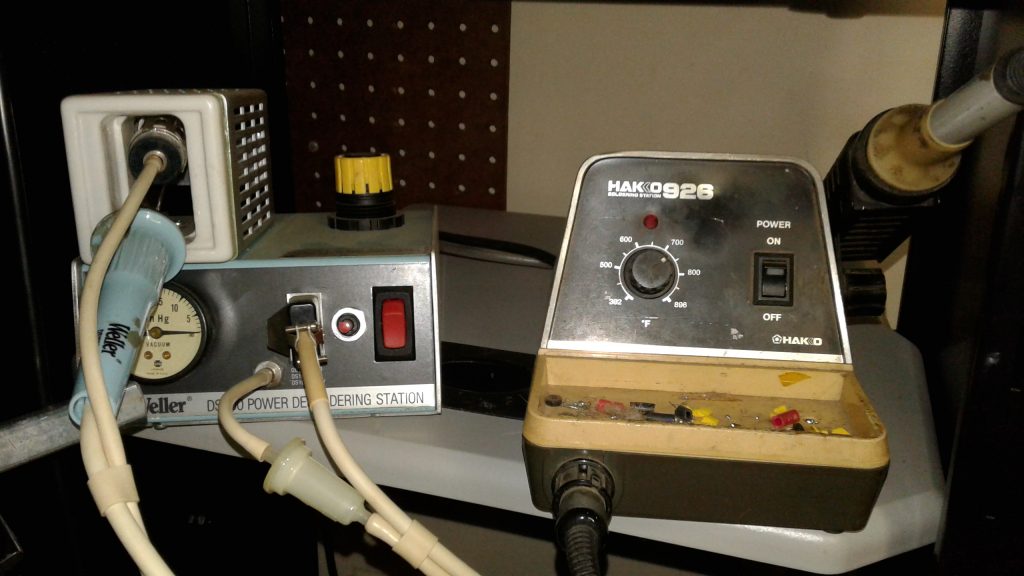

- Weller DS500 Vacuum Desoldering Station (2nd shelf, left) which gets its vacuum supply from the air compressor you see on the bottom shelf, and uses the foot pedal which is sitting on the bottom shelf, to the right of the air compressor.

- Hakko 926 temperature controlled soldering system, which I bought back in 1982. I still have the original tips for that thing and it has worked perfectly since the day I bought it.

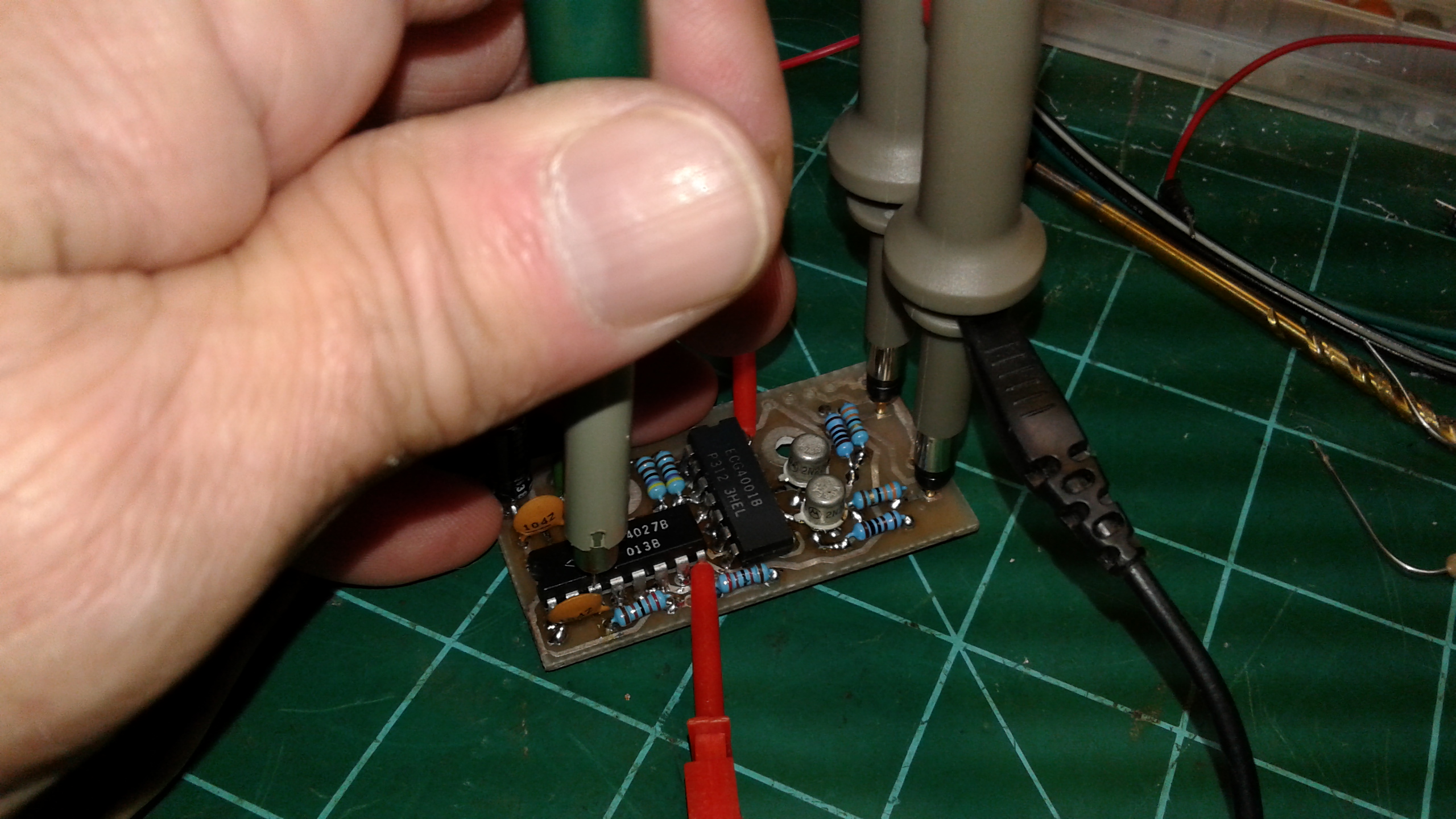

- Panavise board holding and soldering aid.

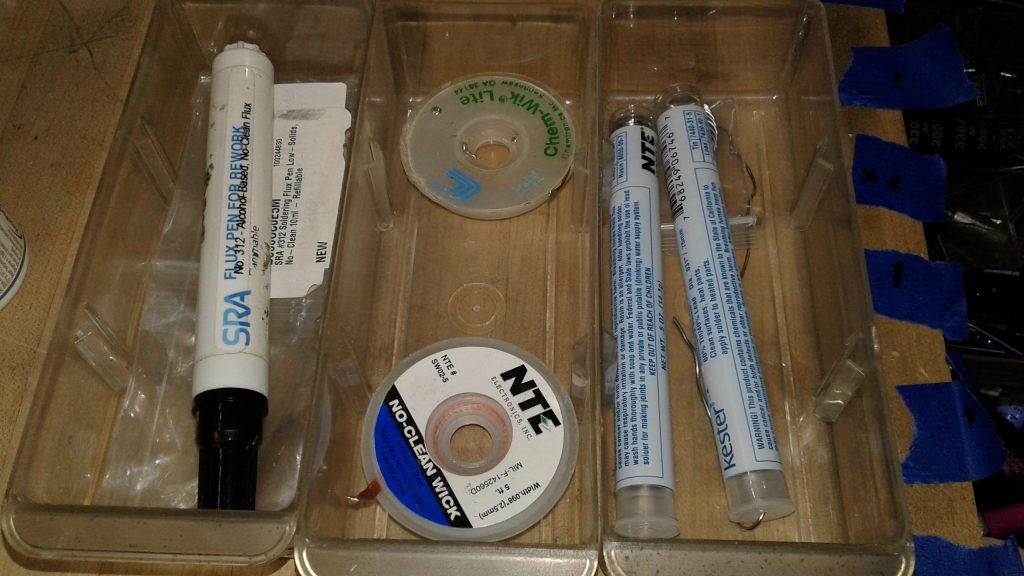

In order to use all these devices, it naturally takes some accessories and supplies. The photos here provide a rundown of the main accessories, but not necessarily everything that gets used in conjunction with the equipment, such as precision diagonal cutters, hemostats, etc., which are all just part of the tools I keep in my Platt technician field tool box and at the workbenches.

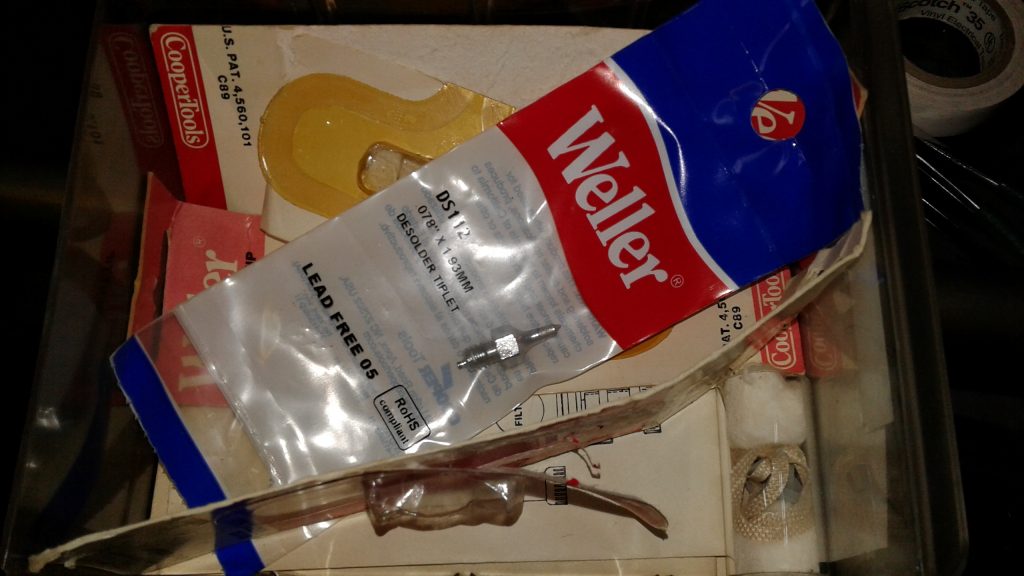

Collection of various size desoldering tips for the DS500, and replacement supplies for the vacuum chamber of the unit.

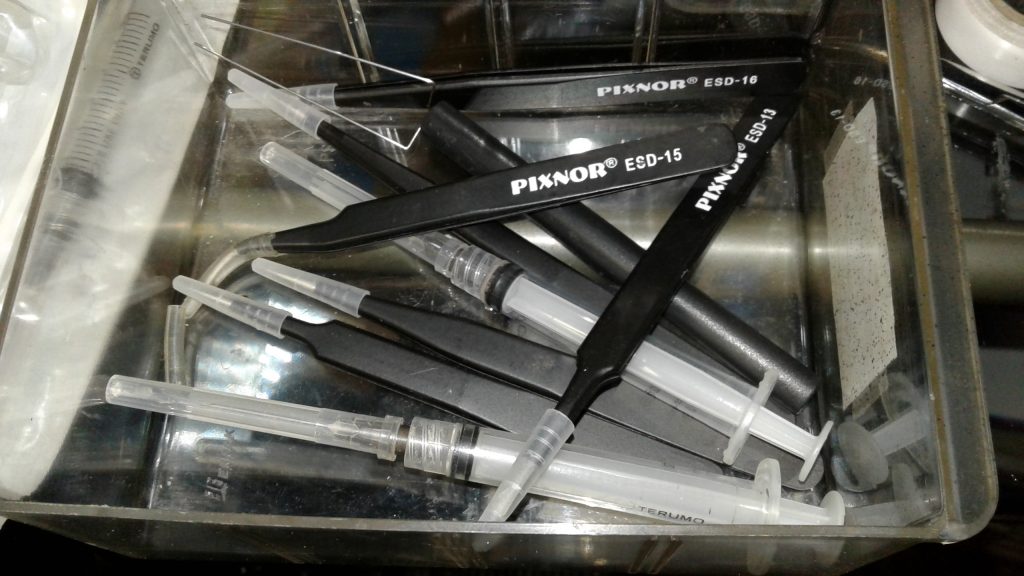

Assorted precision tweezers for soldering work and component handling, along with some of the syringes used to apply solder paste to boards for reflow soldering work.

Kapton tape is a must-have item when doing hot air rework. It is applied to components and traces in close proximity to components being replaced or installed in order to deflect heat and prevent them from damage and solder reflow.

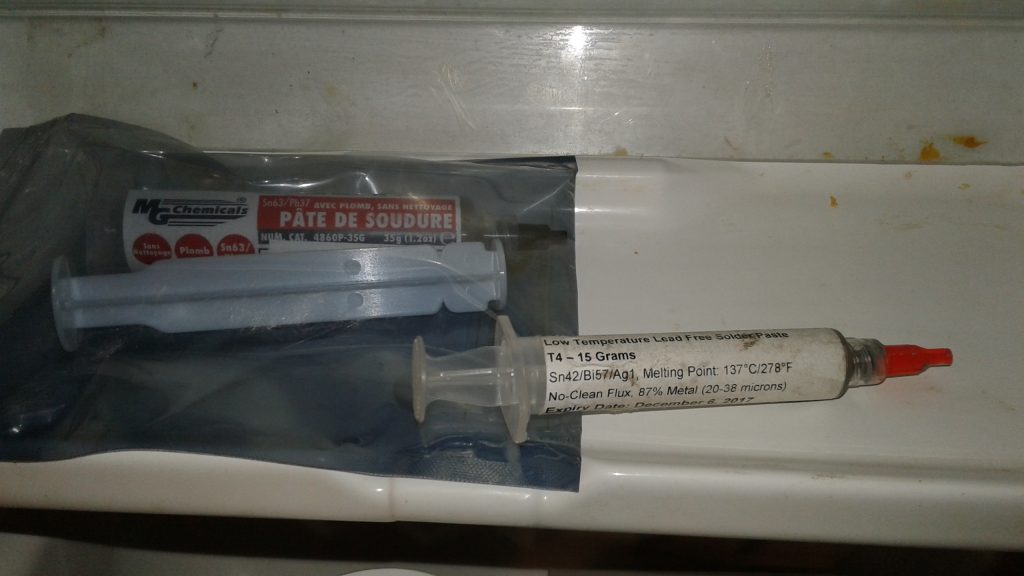

Just to the left of the Sriracha sauce, ketchup, and mustard in the door of my fridge… every ham shack should have solder pastes in their refrigerator. This stuff has to be refrigerated except while being used.

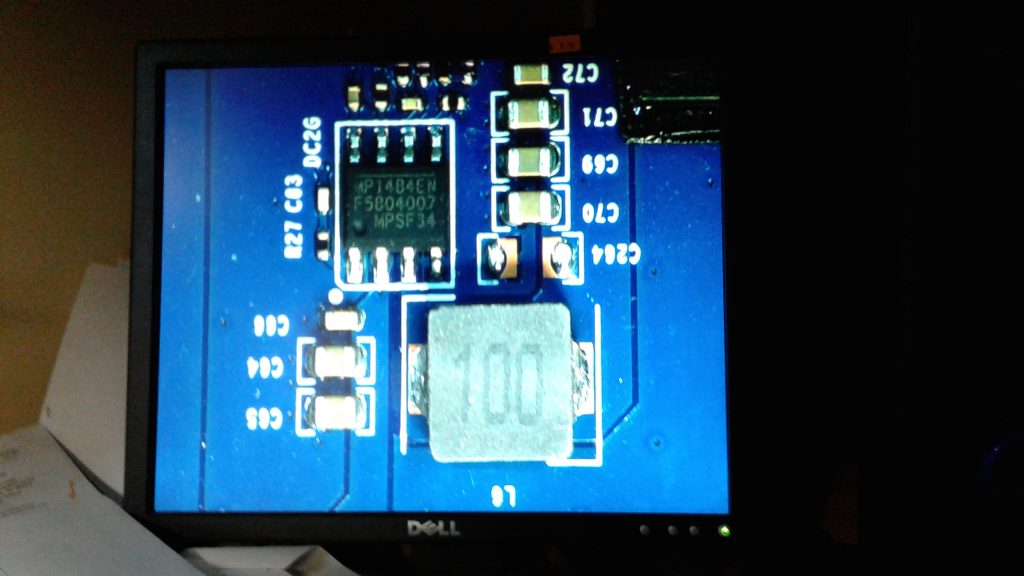

When you enter the world of building and repairing circuits with super-tiny SMD components, having a microscope or similar device becomes a necessity. This is the setup I use for a video microscope. It’s actually a repurposed AverVision PL50 system, originally intended for use for live and online teaching purposes.

High definition video monitor dedicated to the AverVision video magnifier/microscope setup. The Aver system is also connected to the lab PC for capturing stills and video, and the software provides captioning and annotation features, along with a host of other capabilities, including live, online teleconferencing/teaching and streaming software.

Special kit of syringes and blunt-cannula type tips of various sizes and gauges for precisely applying surface mount solder paste to boards.

Collection of Cir-Kit and other brand repair traces, solder pads, vias, etc. for repairing damaged traces and pads/lands on circuit boards. This stuff has rescued many would-be “trashed” circuit boards.

Recent Comments